Quality assurance at West Valley is a continuous process that starts the day a part is received and continues through until the finished part is delivered to the customer. The part is inspected, specifications and purchase order requirements are entered into the process control computer.

The documents that are created will travel through the entire production cycle. Each action is signed and dated to validate the step. This document is the basis for the certificate, which will establish the audit for the processing of the part. West Valley Plating maintains identify laboratory used for analyzing the anodizing and plating solutions on a continuous basis, to ensure consistent quality in the processes. The laboratory is used for research and development for special process projects, based upon customer needs. West Valley is capable of developing solutions to process needs that cannot be met by other companies. West Valley Plating has NADCAP certification of the wet chemistry laboratory for control of the chemical processes.

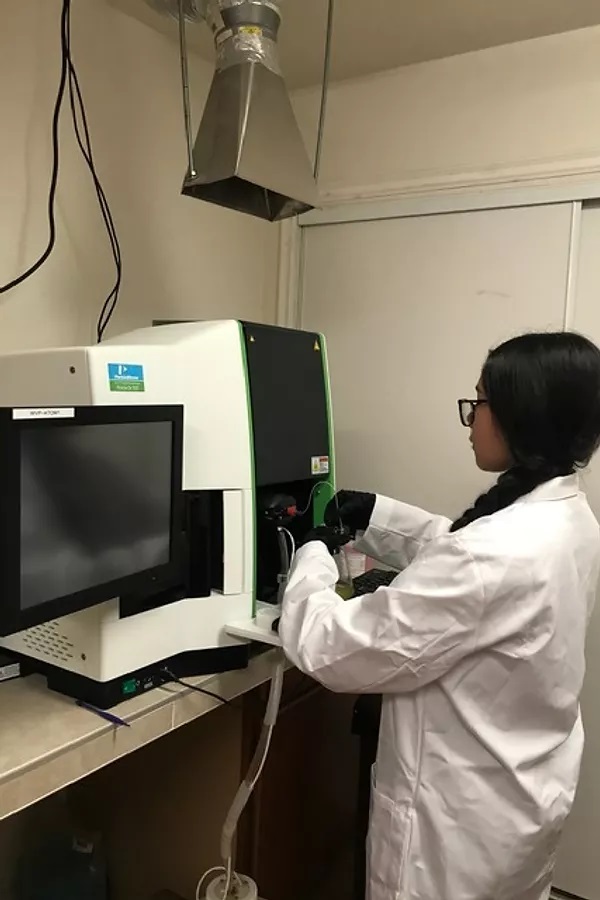

All chemical analysis is performed by laboratory assistants under the direct supervision of Inda Rodriguez, PHD Chemical Engineering.

Equipments

PerkinElmers Pinnacle 500 Atomic Absorption (AA) Spectrophotometer: This equipment is used to precisely monitor bath formulae during plating and anodizing operations, and in the initial bath chemical formulations.

Bowman XRF measurement instrument for precise measurement of plating thickness.

Environmentally controlled laboratory for viscosity measurements for paint/primer and other solutions requiring precise viscosity parameters.

Dual Oxford Machines for plating thickness verification

Photo process examination equipment for microscopic examination of processed parts

Three automatic controlled process ovens salt spray testing and verification equipment microscopes with photo and computer interface for visual examination and documentation of parts.

A NADCAP certified wet chemistry laboratory for control of the chemical processes.