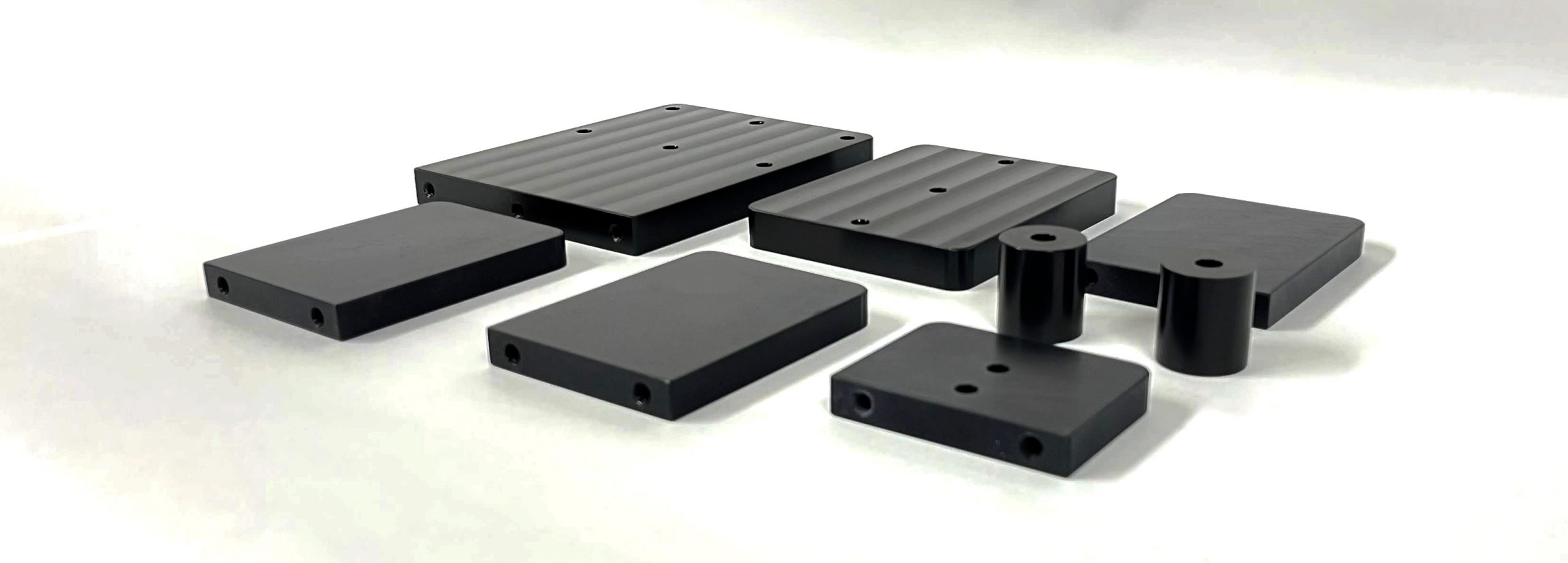

ANODIZING PROCESS

Anodizing is the electrolytic process for forming a very thin layer of a porous aluminum oxide film by reaction of aluminum with oxygen in an acidic solution. This aluminum oxide film gives aluminum parts superior abrasion and corrosion resistance while retaining the numerous properties of the aluminum itself.

We offer two types of anodizing: Anodize Type II and III.

Anodize Type II

Anodizing Type II is carried out at temperatures of 70-80°F. The aluminum oxide layer formed varies from 0.0001 in – 0.0007 in depending on process condition. The porosity of the layer allows for the adsorption of dyes which provides the color of the final product. Sealing of the porous layer is accomplished by a Nickel Acetate Solution, Boiling Water or a Solution of Sodium Dichromate.

Anodize Type III

Anodizing Type III is carried out at a low temperature of 32 – 40° F. Anodize Type III is also known as Hard Anodize. The oxide layer formed during this process is bonded to the underlying substrate and is readily measurable. In the case of a 0.002 in coating, a growth of 0.001 in will be experienced to the other

0.001 in is found below the original surface of the part and it is commonly known as penetration. This apparent 1:1 ratio of buildup versus penetration tends to hold true for most alloys and most coating thickness. The oxide layer formed during anodizing is very hard compared to the hardness of diamond.

The hardness of these coating can reach values of up to 70 on the Rockwell C scale.

Anodize (MIL-A-8625)

- Type IC – Boric Sulfuric*

- Type II – Sulfuric

- Type II Class 2 – Dyed

- Type III – Hard

- Type III Class 2 – Dyed

- Titanium Anodize AMS2488